How to choose a suitable Solid State Relays

Choosing a suitable solid-state relay (SSR) requires considering several key factors to ensure compatibility and optimal performance for your specific application. Here are some steps to guide you through the selection process:

Determine the load requirements

Identify the characteristics of the load you need to control. This includes the load voltage, current, and type (AC or DC). Make sure to consider both the nominal values and any potential surge or inrush currents.

SSR voltage and current ratings

Select an SSR with voltage and current ratings that exceed the requirements of your load. Ensure the SSR can handle the maximum voltage and current levels to prevent overloading and ensure reliable operation.

AC or DC SSR

Choose an SSR suitable for your load type (AC or DC). AC SSRs are designed to control AC loads, while DC SSRs are intended for DC loads. Using an AC SSR for DC loads or vice versa can lead to improper operation or damage.

Control signal compatibility

Determine the control signal type and voltage level that will be used to activate the SSR. SSRs can be activated by various control signals, such as DC voltage, DC current, or logic-level signals. Ensure the control signal matches the input requirements of the SSR you choose.

Zero-crossing or random turn-on

Consider whether you require zero-crossing or random turn-on switching. Zero-crossing SSRs switch the load when the AC voltage crosses zero, minimizing electrical noise and reducing stress on the load. Random turn-on SSRs can switch the load at any point in the AC cycle, which may be more suitable for certain applications.

Heat sinking and thermal management

SSRs generate heat during operation, so consider the thermal requirements and heat sinking capabilities of the SSR. Ensure the SSR has adequate heat dissipation and, if necessary, choose an SSR with a built-in heat sink or plan for external heat sinking.

Additional features

Depending on your application, you may require additional features like built-in transient protection, short-circuit protection, over-current protection, or diagnostic LEDs. Evaluate these features and choose an SSR that provides the necessary functionalities for your specific needs.

Reliability and quality

Consider the reputation and reliability of the manufacturer when selecting an SSR. Look for reputable brands known for producing high-quality, durable products that meet industry standards. Greegoo is a popular brand of SSR manufacturer in India, Poland, Brazil, South Africa, Russia, UAE, Spain, Italy, USA and Germany etc.

Consult datasheets and technical specifications

Review the datasheets and technical specifications of the SSRs you are considering. Pay attention to parameters such as operating temperature range, response time, isolation voltage, and any derating requirements. This information will help you make an informed decision based on your application requirements.

Seek expert advice if needed

If you are unsure about any specific requirements or need assistance, consult with an experienced electrical engineer or contact the manufacturer's technical support for guidance.

By following these steps and considering the specific requirements of your load and application, you can select a suitable solid-state relay that meets your needs effectively.

You may want to know more

- FASTON terminals connection SSR 1 phase ac switching SSR Relay

- What's the difference of Solid State Relay from Magnetic Contactor?

- Integrated IP20 touch-safe Solid State Relays

- DC SSR, Solid State Relay DC Load, DC/AC to DC SSR relay

- Low voltage drop DC SSR, charging and discharging DC SSR launched.

- Greegoo's motor reversing solid state relays introduction

- 1-Phase Solid State Contactors

10A to 180A DC to DC Solid State Relay

10A to 180A DC to DC Solid State Relay, 60V, 100V, 200V, 600V, 1200VDC.

Read More

Excitation technology rectifier components for 30-1350MW steam turbine generators

No maintenance of slip rings and carbon brushes, high reliability; There is no pollution of the motor coil caused by carbon powder and copper powder, and the insulation life is long; No friction sparks, suitable for operation in harsh environments.

Read More

Slim 3 phase Power Diode Module GDF100AA

Power Diode Module DF100AA is designed for three phase full wave rectification, High reliability by unique glass passivation, Isolated mounting base, Output DC current is 100Amp (Tc=102℃), Repetitive peak reverse voltage is up to 1,600V.

Read More

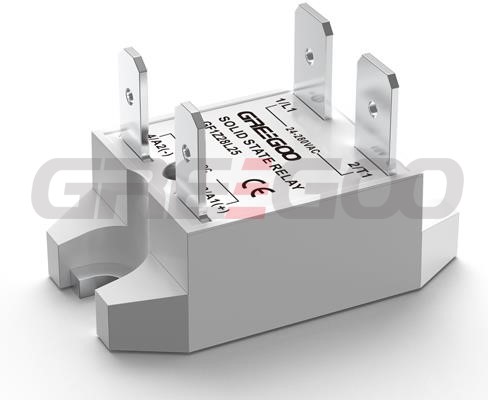

Solid state relays

Greegoo's SSR, solid state relays, structure, appearance, types and features. Single phase, ac switching and dc switching, panel mount and solid state modules, 10A to 400A.

Read More