What's the difference of Solid State Relay from Magnetic Contactor?

Solid-state relays (SSRs) and magnetic contactors are both types of electrical switches used for controlling power circuits. However, they operate on different principles and have distinct characteristics. Here are the key differences between solid-state relays and magnetic contactors:

|

|

1. Operation Principle:

- Solid-State Relay (SSR): An SSR uses semiconductor devices, such as thyristors or triacs, to perform the switching action. These devices are controlled by electronic circuits and do not require any moving parts.

- Magnetic Contactor: A magnetic contactor utilizes an electromagnet to open or close the contacts. When a current flows through the coil, it creates a magnetic field that attracts or repels a set of contacts, causing them to open or close.

2. Switching Speed:

- SSR: Solid-state relays can switch on and off very rapidly, typically in microseconds. They have no mechanical parts, so there are no delays due to physical motion.

- Magnetic Contactor: Magnetic contactors have mechanical components, including moving contacts and an electromagnet. The switching speed is slower compared to SSRs and typically ranges from milliseconds to a few hundred milliseconds.

3. Contact Life and Wear:

- SSR: Since SSRs do not have any moving parts, their contact life is generally longer and more reliable. They are not subject to mechanical wear and tear and can operate for millions of cycles.

- Magnetic Contactor: Magnetic contactors have physical contacts that open and close, leading to mechanical wear over time. The contact life depends on the quality and design of the contactor, but it is generally lower compared to SSRs.

4. Noise and EMI:

- SSR: Solid-state relays produce little to no electrical noise or electromagnetic interference (EMI) since they use semiconductor devices for switching.

- Magnetic Contactor: Magnetic contactors can generate audible noise when the contacts open or close rapidly. Additionally, the switching action of the contacts can produce EMI.

5. Load Compatibility:

- SSR: Solid-state relays are suitable for both resistive and inductive loads. They can handle a wide range of loads, including AC and DC applications.

- Magnetic Contactor: Magnetic contactors are typically used for larger loads, particularly inductive loads such as motors and transformers. They are commonly employed in industrial and HVAC applications.

6. Size and Form Factor:

- SSR: Solid-state relays are generally smaller and more compact compared to magnetic contactors.

- Magnetic Contactor: Magnetic contactors are physically larger due to the presence of mechanical components and coils.

It's important to consider the specific application requirements and load characteristics when choosing between an SSR and a magnetic contactor, as each has its advantages and limitations.

Low voltage drop DC SSR, charging and discharging DC SSR launched.

Low voltage drop DC SSR, charging and discharging SSR

Read More

The Crucial Role of IGBT Modules in Power Electronics and Their Expanding Applications

The Key Role of IGBT Modules in Power Electronics and Modern Applications

Read More

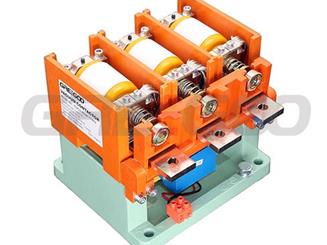

Greegoo's Vacuum Contactors Features and Benefits

Vacuum contactors are electrical devices with high performance, high safety, and high energy efficiency, suitable for various industrial and commercial applications.

Read More

SKKT SKKD SKKH series Thyristior Diode Modules

The SKKT, SKKH and SKKD series Thyristor Diode Modules offer excellent current carrying capacity and low conduction loss, significantly enhancing overall system efficiency.

Read More