Vacuum Contactor

Why do users need vacuum contactor?

- Vacuum contactor can be applied in harsh environments and frequent operation conditions, reducing the maintenance required for electrical components, thereby lowering costs, improving production efficiency, and optimizing the availability of electricity.

Greegoo - Dedicated to Manufacturing Vacuum Contactors

- We have been manufacturing vacuum contactors for a long time, and we continue to strive for improvement. We always engage with our partners in discussions on how to enhance our technology to meet their needs.

Single Phase Vacuum Contactor 400A 630A 1.14KV

GVC1-400A/1140V, GVC1-630A/1140V

1250A/1600A/2000A 2KV Vacuum Contactors Single phase enclosed type

GVC1-1000A/2KV, GVC1-1250A/2KV, GVC1-1600A/2KV, GVC1-2000A/2KV

1250A/1600A/2000A 2KV Vacuum Contactors Single phase enclosed type 2 pole

GVC2-1000A/2KV, GVC2-1250A/2KV, GVC2-1600A/2KV, GVC2-2000A/2KV

GVC9-1400A/1000V vacuum contactor for wind and solar power inverter controlled system

GVC9-800A/1000V, GVC9-1000A/1000V, GVC9-1250/1000V and GVC9-1400A/1000V

1.5KV Vacuum Contactor 160A 250A 400A

GVC11-160A/1.5KV, GVC11-250A/1.5KV, GVC11-400A/1.5KV vacuum contactor and starter

Vacuum Contactor 250A and 400A

GVC6-250A/1.14KV GVC6-400A/1.14KV, GVC20-250A/1.5KV GVC20-400A/1.5KV

630A 800A 1000A Vacuum Contactors

GVC20-630A/1.5KV, GVC20-800A/1.5KV, GVC20-1000A/1.5KV

Vacuum Contactor 1250A 1600A 2000A 2KV

GVC40-1250A/2KV, GVC40-1600A/2KV, GVC40-2000A/2KV

Fast switching low voltage vacuum contactor

GVC30-400A/1.14KV, GVC30-630A/1.14KV, GVC30-800A/1.14KV opening and closing less than 60ms

63A Vacuum Contactor

GVC5-63A/1140V

160A Vacuum Contactor (80A 125A 160A)

GVC5-80A/1140V, GVC5-125A/1140V, GVC5-160A/1140V

EVS-200 vacuum contactors

EVS-200A/1.2KV MINE CONTACTOR

250A Vacuum Contactor

GVC5-250A/1140V

400A Vacuum Contactor GVC5-400A/1140V

GVC5-400A/1140V

630A Vacuum Contactor

GVC313-630A/1140V

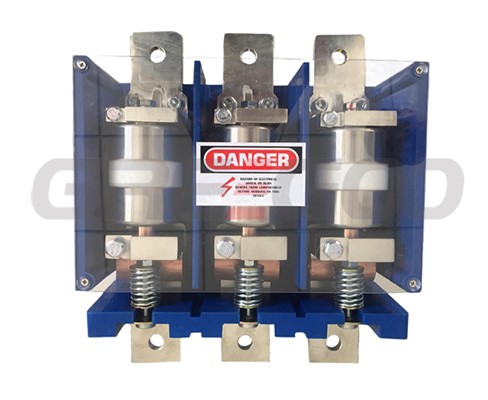

GVC3-800/1000/1250A 3 pole vacuum contactors

GVC3-800A/1140V, GVC3-1000A/1140V, GVC3-1250A/1140V

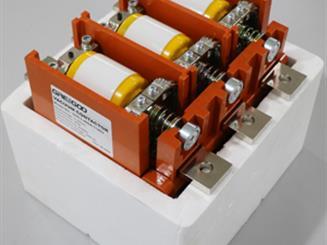

GVC7-1600A 3 pole vacuum contactors

GVC7-1600A/1140V

2000A 2600A 3200A Vacuum Contactor

GVC611-2000A/1.5KV, GVC611-2600A/1.5KV, GVC611-3200A/1.5KV

GVC3-800/1000/1250A 2 pole vacuum contactors

GVC3-800A/1140V 2P, GVC3-1000A/1140V 2P, GVC3-1250A/1140V 2P

GVC7-1600A 2 pole vacuum contactor

GVC7-1600A/1140V.

1600A 1140V single pole Vacuum Contactors

GVC1-1600A/1140V Single Pole high current Vacuum Contactors

1P 63A to 160A @ 1140V Vacuum Contactor

GVC1-63A/0.66KV GVC1-80A/1.14KV, GVC1-125A/1.14KV, GVC1-160A/1.14KV

CKJ50 1000A, 1250A Vacuum Contactors

CKJ50-1000A/1140V, CKJ50-1250A/1140V

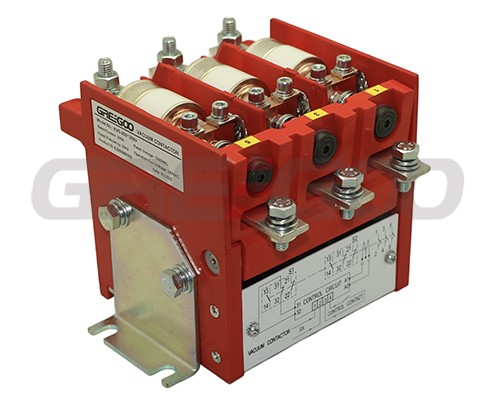

CKJ5-630A/800A/1000A 1140V Vacuum Contactors

CKJ5-630A/1.14KV, CKJ5-800A/1.14KV, CKJ5-1000A/1.14KV

Vacuum Contactor

Knowledge of vacuum contactor

4160V 400Hz 160A Vacuum Contactor

400Hz 4160V 160A Vacuum Contactor, high-voltage rail applications

3.6KV Vacuum Contactor

400A and 630A vacuum contactors, enclosed type.

EVC9-3.6/D400-4T vacuum contactor 3.3KV vacuum contactor

3.6kv, 400A open frame vacuum starter, 3.3kv Vacuum Contactor starter, 3.3kv vacuum contactor

EVC3-3.6/D800/1000/1250A vacuum contactor

3.6KV, 800A, 1000A, 1250A.

CNF-400A/1.14KV Fast Vacuum Contactor

400A 1140V bypass switch

3.6KV Fast Vacuum Contactors (bypass switch)

Making or breaking time is less than 5ms vacuum contactor as by-pass switch.

800A 3.6KV Vacuum Contactor

800A 3.6KV

Three-Phase AC Isolating Reversing Switch

800A 3.6KV

Vacuum isolating phase change switch 3.6KV 800A

800A 3.6KV

Three Phase AC Isolating Reversing Switch GHC79-700A/3.6KV

700A 3.6KV

Vacuum isolating phase change switch

800A 1.14KV

Vacuum isolating phase change switch 630A 1.14KV

630A 1.14KV

Three-Phase AC Isolating Phase Change Switch 1.14KV

500A 1.14KV

Vacuum insulated disconnect switch with phase change

400A 1.14KV

Vacuum reversing disconnect switches

200A 1.14KV

Single Pole Vacuum Contactor

7.2KV, 12KV, 160A, 250A, 400A and 630A.

EVC1-12/160~630-6.3G single pole high altitude 12kv vacuum contactor

630A 12KV. Altitude upto 4000 meters, single phase vacuum contactor.

7.2KV 12KV Vacuum Contactor 160A to 630A

6.6KV/7.2kV and 11KV/12kV Vacuum Contactor starter, 160A to 630A for a variety of power control, 7.2kv vacuum contactor, 11kv vacuum contactor, mv vacuum contactor.

Medium Voltage Vacuum Contactor EVC8C-7.2KV/12KV

7.2kV and 12kV Vacuum Contactor, 250A to 800A, general purpose vacuum contactor, 6.6KV Vacuum Contactor, 11kv Vacuum Contactor.

12kV 630A single phase vacuum contactor

160A,250A,400A and 630A 12KV single phase casting type vacuum contactors

6.6kV 7.2kV Vacuum Contactor

160A,250A,400A and 630A 6.6/7.2KV single phase casting type vacuum contactors

12KV high-proto type high altitude vacuum contactor

250A,400A,630A,800A and 1000A 12KV high-proto type vacuum contactor, Altitude up to 4000 meters casting type three phase vacuum contactor.

12KV Latching Hybrid Vacuum Switchgear

12KV, 400A to 1250A, vacuum contactor and vacuum circuit breaker combined vacuum switch

12KV 1600A 2000A 2500A Vacuum Contactor

12KV 1600A, 2000A, 2500A

AC high voltage vacuum contactor with fuse composite apparatus

7.2kV and 12kV drawer type removable vacuum contactor, 200A and 315A, fuse limit current protection, breaking capacity up to 40kA.

Compact Medium Voltage Vacuum Contactor EVC4-160A to 630A 12KV

12KV 160A, 250A, 400A, 630A Vacuum Contactor

EVC8 12KV 250A 400A and 630A Vacuum Contactor

250A, 400A and 630A, economical type

EVC7-12-160/250/400/630G

160A,250A,400A,630A 12KV. Altitude upto 4000 meters

CKG4 12KV Vacuum Contactor

12KV 160A, 250A, 400A and 630A MV vacuum contactor

24KV Vacuum Contactor 160A to 1250A EVC8G

Single and 3 pole 24KV vacuum contactor, 160A to 1250A.

630A 1P EVC20-630/1P-24KV high voltage vacuum contactors

1P 630A 24KV vacuum contactor, high voltage vacuum contactor

EVC20 24KV 630A 3 pole Vacuum Contactors

24kV 630A 3 pole, high voltage vacuum contactors

36KV Vacuum Contactor (EVC9)

40.5KV, 35KV, 36KV permanet magnetic latching vacuum contactor

40.5KV High Voltage Vacuum Contactors

Three pole vacuum contactors, 36kV/40.5kV, 630A and 1250A, 36kv vacuum contactor, high voltage vacuum contactor.

EVC1-40.5KV-160/250/400/630A Vacuum Contactor

Single phase Vacuum Contactor, 1P 36kV Vacuum Contactor, 40.5kv vacuum contactor

The main function of a vacuum contactor is simply to make and break the connection between the power source and the load. It is specifically designed for medium voltage applications, typically ranging from 1.14kV to 40.5kV. The use of a vacuum ensures that the arc typically generated during the switching process is eliminated, which extends the life of the contactor and reduces maintenance requirements.

Here are some of the benefits of using a vacuum contactor:

Arc Suppression: The vacuum effectively suppresses the electrical arc that can occur when contacts within a contactor open or close, thus preventing damage to the system.

Longevity: Vacuum contactors tend to have a longer lifespan compared to other types of contactors because the contacts are less susceptible to wear and degradation due to the lack of atmospheric conditions that could lead to oxidation.

Reliability: The sealed vacuum environment provides consistent performance over a wide range of operating conditions and reduces the likelihood of faults, leading to increased reliability.

Safety: By containing the contacts within a vacuum, the risk of fire and explosion is significantly reduced, which enhances the overall safety for operators and equipment.

Compact Design: Vacuum contactors are generally smaller than their air-insulated or oil-insulated counterparts, which saves space in electrical panels and switchgear.

Low Maintenance: With fewer parts exposed to wear and no need for gases or oils that require regular replacement or maintenance, vacuum contactors are low maintenance.

Noise Reduction: The operation of a vacuum contactor is quieter, which is beneficial in environments where noise pollution is a concern.

Vacuum contactors are commonly used in industrial motor starters, transformer switching, capacitor switching, and other applications where efficient, reliable high-voltage switching is required.

Medium voltage vacuum contactors are specialized electrical switches designed for medium-voltage power systems. They utilize vacuum interrupters to extinguish arcs when contacts are opened or closed. These contractors offer advantages such as enhanced safety, longevity, and low maintenance.

The vacuum contactor is mainly composed of a vacuum interrupter and an operating mechanism. The vacuum interrupter has two functions of reliable arc extinguishing when passing the normal operating current and frequently switching the operating current. But it cannot cut off the overload and short-circuit current.

Fast vacuum contactors are widely used as bypass switches due to their quick operation (<5 milliseconds), high reliability, and high current tolerance. They ensure continuous power supply during main circuit faults or maintenance, making them ideal for scenarios requiring rapid response and efficient power management.

The main difference between medium voltage and low voltage vacuum contactor lies in their voltage range and application scenarios. Medium voltage vacuum contactors are used in systems ranging from 3.6kV to 36kV, suitable for controlling and protecting medium voltage motors. Low voltage vacuum contactors are used below 2kV, suitable for low voltage motors and equipment. Medium voltage contactors are more robustly designed and costlier, while low voltage contactors are more compact, fitting well in low voltage distribution cabinets.

Vacuum contactors are electrical switching devices used to control low and medium voltage circuits, typically in the range of 1.14kV to 40.5kV. They operate by using a vacuum interrupter to extinguish the arc formed when electrical contacts open or close, ensuring reliable switching with minimal wear. The vacuum environment prevents oxidation and contamination of the contacts, making them durable and suitable for frequent operations.

Vacuum contactors are electrical switching devices used for frequent load switching in low and medium voltage systems (1.14kV-40.5kV). They utilize a vacuum interrupter to extinguish arcs, ensuring reliable, low-maintenance operation with minimal contact wear. Unlike circuit breakers, which are designed for fault interruption and high breaking capacity, vacuum contactors are optimized for repetitive switching of normal loads, such as motors, transformers, or capacitor banks. They are compact, cost-effective, and widely used in industries like mining and manufacturing. Vacuum Circuit breakers, however, prioritize protection against short circuits and overloads, making them less suitable for frequent switching but essential for system safety.

What is the difference between the magnetic latching type and electrical holding type vacuum contactor?

Vacuum contactors can be classified into two main types based on their mechanism for holding the contacts closed: magnetic latching type and electrical holding type.

Read More

12KV Vacuum Contactor with Vacuum Circuit Breaker Integrated - Frequent Switching under Higher Breaking Capacity 31.5kA

12KV 630A to 1250A 31.5KA Vacuum Contactor + Vacuum Circuit Breaker, frequently switching under high breaking capacity

Read More

Vacuum Contactor vs. AC Contactor, What is the Differences?

Vacuum contactors provide superior durability and low maintenance for high-voltage systems, while AC contactors are cost-effective and versatile for lower-voltage needs.

Read More

Exploring the Unique Features of the GHFVC-160A/5kV Vacuum Contactor - 400Hz, Magnetic Latching and Rail Applications

400Hz high-frequency design, magnetic latching mechanism, and optimization for rail applications

Read More