DC Solid State Relay - 120A to 2000A 100V to 1200V

Home Products DC to DC Solid State RelayDC output solid state relayDC Solid State Relay - 120A to 2000A 100V to 1200V

DC Solid State Relay - 120A to 2000A 100V to 1200V

- Electromagnetic coupling isolation between input and output circuits.

- Control signal interface with PLC, TTL logic.

- Light-emitting diode indicates operating status.

- Built-in input undervoltage protection, output transient overvoltage absorption protection.

- Solid non-contact output, fast switching speed, no spark and no arcing on and off.

- Epoxy resin encapsulation, anti-corrosion, fire and shock resistance, stable and reliable switch work.

- The product is mainly used in the new energy vehicles of high-power DC appliances non-contact switch. Such as PTC DC heater, battery charging and discharging, DC motor, solenoid valve and other switching switches.

| Description | DC Solid State Relay, DC input DC output Solid State Relay, DC-DC Solid state relay, DC SSR, DC controlled DC load solid state relay, DC input DC load solid state relay, Solid state DC relay,DC-DC SSR |

| Control power | 12-15VDC / 18-36VDC |

| Control current | 30~80 mA/25-70mA |

| Undervoltage protection | <10VDC self-locking / <16VDC self-locking |

| On-off time | ≤1mS (120A-200A); ≤5mS (300A-2000A) |

| Working Instruction | LED |

| Maximum output voltage | 100VDC,200VDC, 600VDC, 1200VDC |

| Max. load current | 120, 150, 180, 200, 300 ...... 2000 A |

| On-state voltage drop | ≤1.0 ~ 4.0 V |

| Off-statevoltage | ≥100V ≥200V ≥600V ≥1200V |

| Overvoltage protection | Transient protection voltage are: 80V, 180V, 470V, 1000V |

| Switching Characteristics | MOSFET or IGBT-solid-state non-contact switching characteristics |

| Isolation voltage | ≥ 1800~2500 V |

| Insulation voltage | ≥ 2000~2500 V |

| Operating Temperature | -25~75℃ |

| Insulation resistance | ≥ 100 MΩ |

| Heat dissipation conditions | Equipped with heat sink and fan for strong cooling |

| Safety factor of load current | 2.5-4 times for resistive load 3-6 times for inductive load |

| Dimension | 95×39×48; 120×52×40; 135×69×50 |

Note: For Overcurrent protection(GDR02/08LA): 50% of the marked current setting; Short circuit protection(GDR02/08ZA): 100% of the marked current setting.

| MODEL | RATED CURRENT | VOLTAGE RANGE | CONTROL | CASING |

| GDZ02-10100ZD3 | 10A | 100VDC | 4-32VDC | J-7 |

| GDZ02-20100ZD3 | 20A | 100VDC | 4-32VDC | J-7 |

| GDZ02-30100ZD3 | 30A | 100VDC | 4-32VDC | J-7 |

| GDZ02-40100ZD3 | 40A | 100VDC | 4-32VDC | J-7 |

| GDZ02-50100ZD3 | 50A | 100VDC | 4-32VDC | J-7 |

| GDZ02-60100ZD3 | 60A | 100VDC | 4-32VDC | J-7 |

| GDZ02-80100ZD3 | 80A | 100VDC | 4-32VDC | J-7 |

| GDZ02-100100ZD3 | 100A | 100VDC | 4-32VDC | J-7 |

| GDZ02-120100ZD3 | 120A | 100VDC | 4-32VDC | J-7 |

| GDZ02-150100ZD3 | 150A | 100VDC | 4-32VDC | J-7 |

| GDZ02-180100ZD3 | 180A | 100VDC | 4-32VDC | J-7 |

| GDZ02-200100ZD3 | 200A | 100VDC | 4-32VDC | J-7 |

| GDZ02-10200ZD3 | 10A | 200VDC | 4-32VDC | J-7 |

| GDZ02-20200ZD3 | 20A | 200VDC | 4-32VDC | J-7 |

| GDZ02-30200ZD3 | 30A | 200VDC | 4-32VDC | J-7 |

| GDZ02-40200ZD3 | 40A | 200VDC | 4-32VDC | J-7 |

| GDZ02-50200ZD3 | 50A | 200VDC | 4-32VDC | J-7 |

| GDZ02-60200ZD3 | 60A | 200VDC | 4-32VDC | J-7 |

| GDZ02-80200ZD3 | 80A | 200VDC | 4-32VDC | J-7 |

| GDZ02-100200ZD3 | 100A | 200VDC | 4-32VDC | J-7 |

| GDZ02-120200ZD3 | 120A | 200VDC | 4-32VDC | J-7 |

| GDZ02-150200ZD3 | 150A | 200VDC | 4-32VDC | J-7 |

| GDZ02-180200ZD3 | 180A | 200VDC | 4-32VDC | J-7 |

| GDZ02-10400ZD3 | 10A | 400VDC | 4-32VDC | J-7 |

| GDZ02-20400ZD3 | 20A | 400VDC | 4-32VDC | J-7 |

| GDZ02-30400ZD3 | 30A | 400VDC | 4-32VDC | J-7 |

| GDZ02-40400ZD3 | 40A | 400VDC | 4-32VDC | J-7 |

| GDZ02-50400ZD3 | 50A | 400VDC | 4-32VDC | J-7 |

| GDZ02-60400ZD3 | 60A | 400VDC | 4-32VDC | J-7 |

| GDZ02-80400ZD3 | 80A | 400VDC | 4-32VDC | J-7 |

| GDZ02-100400ZD3 | 100A | 400VDC | 4-32VDC | J-7 |

| GDZ02-120400ZD3 | 120A | 400VDC | 4-32VDC | J-7 |

| GDZ02-150400ZD3 | 150A | 400VDC | 4-32VDC | J-7 |

| GDZ02-180400ZD3 | 180A | 400VDC | 4-32VDC | J-7 |

| GDZ02-10600ZD3 | 10A | 600VDC | 4-32VDC | J-7 |

| GDZ02-20600ZD3 | 20A | 600VDC | 4-32VDC | J-7 |

| GDZ02-30600ZD3 | 30A | 600VDC | 4-32VDC | J-7 |

| GDZ02-40600ZD3 | 40A | 600VDC | 4-32VDC | J-7 |

| GDZ02-50600ZD3 | 50A | 600VDC | 4-32VDC | J-7 |

| GDZ02-60600ZD3 | 60A | 600VDC | 4-32VDC | J-7 |

| GDZ02-80600ZD3 | 80A | 600VDC | 4-32VDC | J-7 |

| GDZ02-100600ZD3 | 100A | 600VDC | 4-32VDC | J-7 |

| GDZ02-120600ZD3 | 120A | 600VDC | 4-32VDC | J-7 |

| GDZ02-150600ZD3 | 150A | 600VDC | 4-32VDC | J-7 |

| GDZ02-180600ZD3 | 180A | 600VDC | 4-32VDC | J-7 |

| GDZ02-101200ZD3 | 10A | 1200VDC | 4-32VDC | J-7 |

| GDZ02-201200ZD3 | 20A | 1200VDC | 4-32VDC | J-7 |

| GDZ02-301200ZD3 | 30A | 1200VDC | 4-32VDC | J-7 |

| GDZ02-401200ZD3 | 40A | 1200VDC | 4-32VDC | J-7 |

| GDZ02-501200ZD3 | 50A | 1200VDC | 4-32VDC | J-7 |

| GDZ02-601200ZD3 | 60A | 1200VDC | 4-32VDC | J-7 |

| GDZ02-801200ZD3 | 80A | 1200VDC | 4-32VDC | J-7 |

| GDZ02-1001200ZD3 | 100A | 1200VDC | 4-32VDC | J-7 |

| GDZ02-1201200ZD3 | 120A | 1200VDC | 4-32VDC | J-7 |

| GDZ02-1501200ZD3 | 150A | 1200VDC | 4-32VDC | J-7 |

| GDZ02-1801200ZD3 | 180A | 1200VDC | 4-32VDC | J-7 |

M2-D Casing

|

MODEL |

RATED CURRENT | VOLTAGE RANGE | CONTROL | CASING |

| GDZ08-120100ZD3 | 120A | 100VDC | 4-32VDC | M-2D |

| GDZ08-150100ZD3 | 150A | 100VDC | 4-32VDC | M-2D |

| GDZ08-200100ZD3 | 200A | 100VDC | 4-32VDC | M-2D |

| GDZ08-300100ZD3 | 300A | 100VDC | 4-32VDC | M-2D |

| GDZ08-400100ZD3 | 400A | 100VDC | 4-32VDC | M-2D |

| GDZ08-500100ZD3 | 500A | 100VDC | 4-32VDC | M-2D |

| GDZ08-600100ZD3 | 600A | 100VDC | 4-32VDC | M-2D |

| GDZ08-120200ZD3 | 120A | 200VDC | 4-32VDC | M-2D |

| GDZ08-150200ZD3 | 150A | 200VDC | 4-32VDC | M-2D |

| GDZ08-200200ZD3 | 200A | 200VDC | 4-32VDC | M-2D |

| GDZ08-300200ZD3 | 300A | 200VDC | 4-32VDC | M-2D |

| GDZ08-400200ZD3 | 400A | 200VDC | 4-32VDC | M-2D |

| GDZ08-120600ZD3 | 120A | 600VDC | 4-32VDC | M-2D |

| GDZ08-150600ZD3 | 150A | 600VDC | 4-32VDC | M-2D |

| GDZ08-200600ZD3 | 200A | 600VDC | 4-32VDC | M-2D |

| GDZ08-300600ZD3 | 300A | 600VDC | 4-32VDC | M-2D |

| GDZ08-400600ZD3 | 400A | 600VDC | 4-32VDC | M-2D |

| GDZ08-500600ZD3 | 500A | 600VDC | 4-32VDC | M-2D |

| GDZ08-1201200ZD3 | 120A | 1200VDC | 4-32VDC | M-2D |

| GDZ08-1501200ZD3 | 150A | 1200VDC | 4-32VDC | M-2D |

| GDZ08-2001200ZD3 | 200A | 1200VDC | 4-32VDC | M-2D |

| GDZ08-3001200ZD3 | 300A | 1200VDC | 4-32VDC | M-2D |

| GDZ08-4001200ZD3 | 400A | 1200VDC | 4-32VDC | M-2D |

| GDZ08-5001200ZD3 | 500A | 1200VDC | 4-32VDC | M-2D |

M-3/M-3D Casing

| GDZ08-800100ZD3 | 800A | 100VDC | 4-32VDC | M-3 |

| GDZ08-1000100ZD3 | 1000A | 100VDC | 4-32VDC | M-3 |

| GDZ08-1200100ZD3 | 1200A | 100VDC | 4-32VDC | M-3 |

| GDZ08-1500100ZD3 | 1500A | 100VDC | 4-32VDC | M-3D |

| GDZ08-1800100ZD3 | 1800A | 100VDC | 4-32VDC | M-3D |

| GDZ08-2000100ZD3 | 2000A | 100VDC | 4-32VDC | M-3D |

| GDZ08-500200ZD3 | 500A | 200VDC | 4-32VDC | M-3 |

| GDZ08-600200ZD3 | 600A | 200VDC | 4-32VDC | M-3 |

| GDZ08-600600ZD3 | 600A | 600VDC | 4-32VDC | M-3 |

| GDZ08-800600ZD3 | 800A | 600VDC | 4-32VDC | M-3 |

| GDZ08-1000600ZD3 | 1000A | 600VDC | 4-32VDC | M-3 |

| GDZ08-1200600ZD3 | 1200A | 600VDC | 4-32VDC | M-3D |

| GDZ08-1500600ZD3 | 1500A | 600VDC | 4-32VDC | M-3D |

| GDZ08-1800600ZD3 | 1800A | 600VDC | 4-32VDC | M-3D |

| GDZ08-2000600ZD3 | 2000A | 600VDC | 4-32VDC | M-3D |

| GDZ08-6001200ZD3 | 600A | 1200VDC | 4-32VDC | M-3 |

| GDZ08-8001200ZD3 | 800A | 1200VDC | 4-32VDC | M-3 |

| GDZ08-10001200ZD3 | 1000A | 1200VDC | 4-32VDC | M-3 |

Note: Control voltage 9-72vdc , Normal Close type SSR, Over-current protection can be custom-made to meet your demand.

Selection Guide:

A margin should be left when selecting the voltage and current of the product. For resistive load: the current is selected according to 2.5~4 times the load current, and the voltage is selected according to 2~2.5 times the load power. Inductive load: current is selected according to 3-7 times load current, voltage is selected according to 2.5-3 times load voltage. According to the relationship between load current and ambient temperature, when the ambient temperature is high or heat dissipation conditions are not good, the current capacity of the solid state relay should be increased accordingly.

In order to prevent the product from short-circuiting during use, it is necessary to connect a fast circuit breaker or a fast fuse in series with the product in the load circuit.

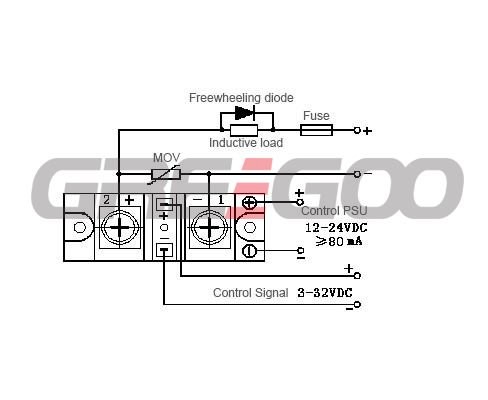

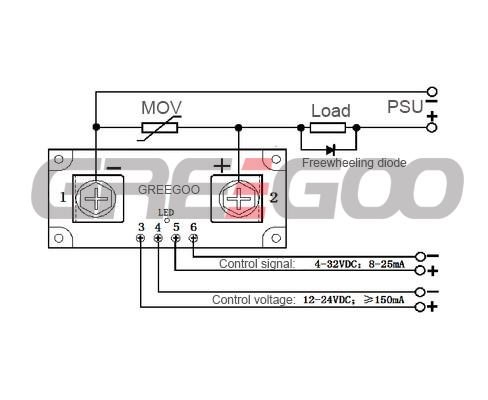

For inductive loads, a freewheeling diode must be connected to both ends of the load, and a varistor must be connected to the output end (the varistor (MOV) is selected according to 1~1.5 times of the power supply voltage) to prevent the high voltage generated during switching from damaging the solid-state switch.

When the product is installed, it is required that the contact surface between the heatsink and the product must be flat and clean, and a layer of thermally conductive silicone grease is applied to its surface, and then finally the screws set with flat washers andSpring washersare tightened symmetrically to fix.

In modern industrial and household appliances, relays play a crucial role. With technological advancements, DC Solid State Relays (DC SSR) have become a star product in the field of electrical control due to their unique advantages.

What is a DC Solid State Relay?

A DC Solid State Relay is an electronic switching device without mechanical moving parts. Unlike traditional electromagnetic relays, solid state relays use semiconductor devices (such as thyristors, triacs, etc.) to open and close circuits. Without mechanical contacts, solid state relays offer longer service life and higher reliability.

Advantages of DC Solid State Relays

-

No Mechanical Wear: With no moving parts, solid state relays are not affected by mechanical wear, resulting in a longer lifespan.

-

Fast Response: The switching speed of solid state relays is extremely fast, usually in the millisecond range, making them suitable for applications requiring quick response.

-

Noise-Free: There is no mechanical action during switching, so no noise is generated, making them ideal for applications requiring a quiet environment.

-

High Durability: Capable of withstanding frequent switching operations without affecting performance.

Application

DC Solid State Relays are widely used in industrial automation, transportation, household appliances, and renewable energy systems. For example, in solar power systems, solid state relays are used to control the flow of current, ensuring efficient system operation.

How to Choose the Right DC Solid State Relay?

When selecting a suitable DC Solid State Relay, consider the following factors:

- Voltage and Current: Ensure the relay's rated voltage and current meet the application requirements.

- Load Type: Choose the appropriate relay based on the nature of the load (e.g., resistive, inductive, or capacitive load).

- Heat Dissipation Requirements: Solid state relays generate heat during operation, requiring good thermal design to prevent overheating.

Need more information?

Contact us to request pricing, availability and customization options.

DC solid state relay with over-current and over-voltage protection

DC Solid State Relay, 120-2000A,100-1200VDC, over-current and over voltage protection type.

View More.jpg)

GDZ02A DC solid state relay for inductive load

10A to 30A, 100V to 400VDC, inductive load

View More

Three channel output dc solid state relay (GDZ033)

30-200A, 100V to 1200V, 3 channel ouput dc ssr.

View More

GDZ02 DC output solid state relay

10A to 180A, 100V to 1200VDC

View More