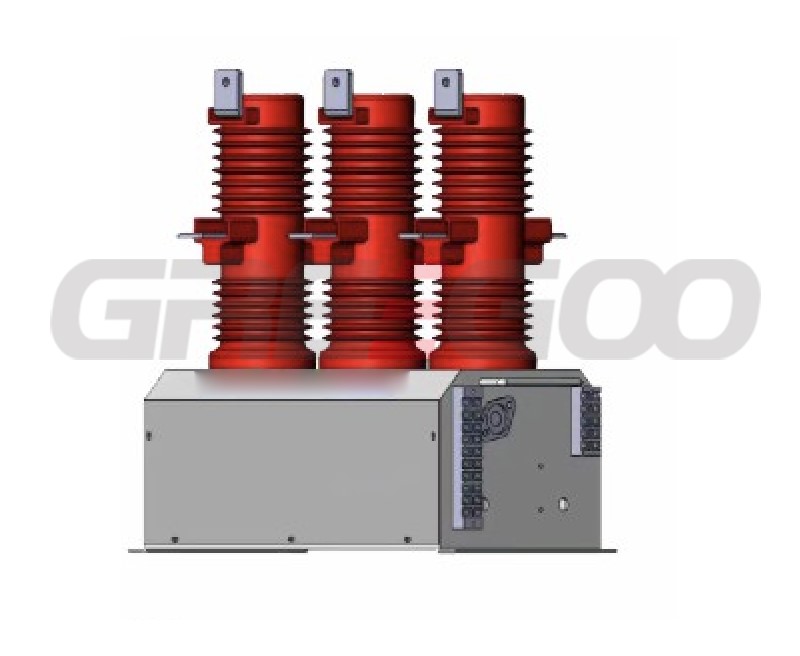

12KV Latching Hybrid Vacuum Switchgear

Home Products Vacuum ContactorMedium Voltage Vacuum Contactor (7.2/12kV)12KV Latching Hybrid Vacuum Switchgear

12KV Latching Hybrid Vacuum Switchgear

The product combining a vacuum contactor and a vacuum circuit breaker is typically called vacuum switchgear or a hybrid vacuum switchgear. It's also refer to it as a medium-voltage switchgear assembly or use specific product names like vacuum contactor-breaker combination or integrated vacuum switchgear.

The G3NA series high-voltage permanent magnet latching vacuum contactor/switch (hereinafter referred to as the "contactor") is suitable for power network systems with AC frequency of 50-60Hz, a rated voltage of 12KV in the main circuit, and rated currents ranging from 400A to 1250A. It is designed for remote connection and disconnection, as well as frequent starting and control of AC motors, transformers, capacitor banks, and other applications.

Environmental Conditions for Use:

Ambient temperature: -25°C to 40°C.

Installation altitude: Not exceeding 2000m.

Relative humidity of the air: The maximum relative humidity in the wettest month is 90%, and the average minimum temperature of the month is 25°C.

Consideration should be given to frost formation on the product surface due to temperature changes.

Structure and Operating Principles

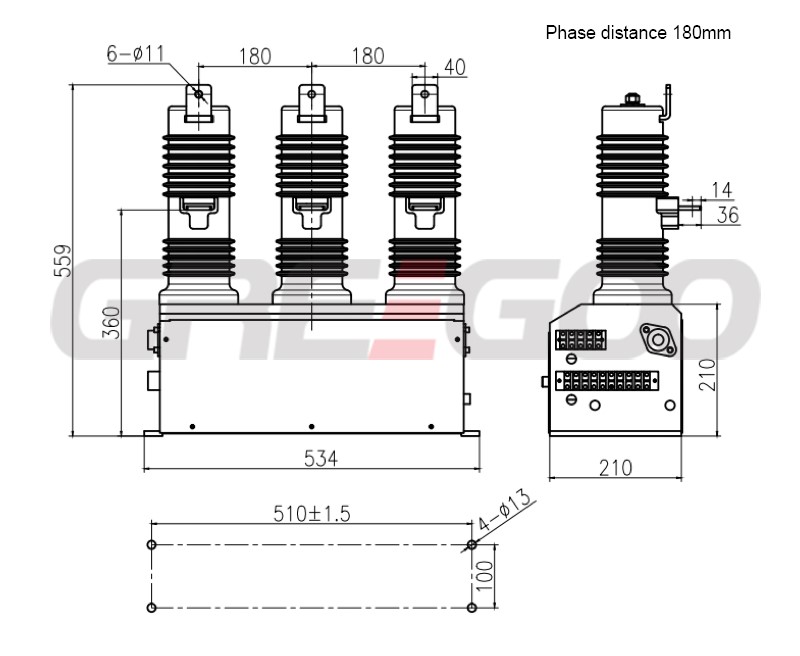

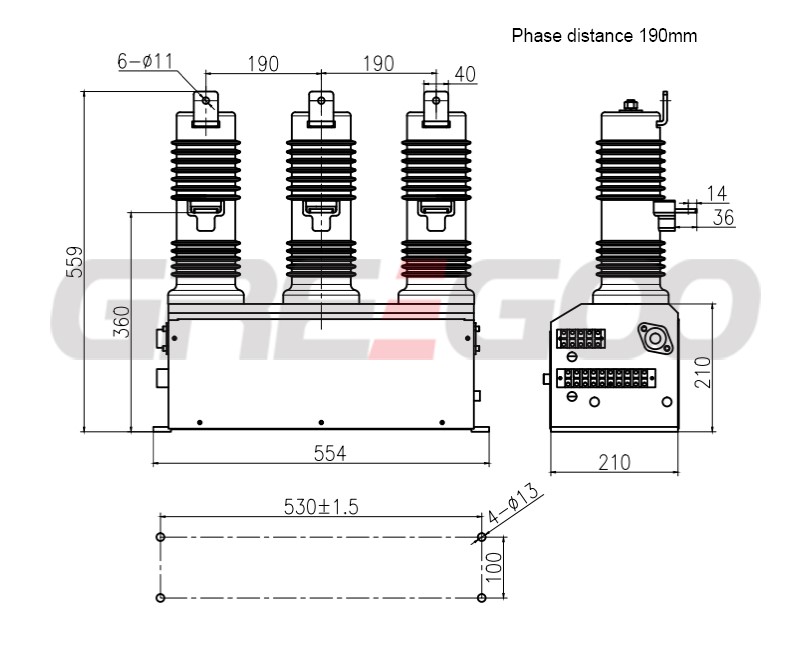

Structure:

This series of switches is composed of an insulated separating frame, a transmission lever, an electromagnetic system, auxiliary switches, and a vacuum contactor tube. The structure features a high-voltage circuit and a low-voltage control with a vertically separated design. It is aesthetically pleasing, safe, reliable, and easy to install and maintain.

Operating Principles:

Permanent Magnet Type:

This series of vacuum contactors adopts the most advanced bistable permanent magnet operating mechanism as the main driving component. With few operating elements and simple control, it has a low closing and opening current, ensuring safety and reliability. In the closed or open state, the control circuit does not need a long-term live power supply, achieving energy-saving and reliable effects.

Vacuum Contactor Tube (Vacuum Arc Extinguishing Chamber):

This component is the heart of the contactor, consisting of upper and lower cover plates, a glass or ceramic outer shell, a corrugated tube, and moving and fixed conductive rods. It forms a sealed chamber and is evacuated to high vacuum. The moving and fixed conductive rods are welded with a pair of wear-resistant current-interrupting materials to create a good breaking contact. The corrugated tube serves to isolate the atmosphere and allows the contact to move up and down.

Due to the vacuum chamber, the vacuum tube cannot withstand external impacts, and the corrugated tube cannot undergo rotational distortion; otherwise, it may leak air and become damaged.

| Model | G3NA-400/12 | G3NA-630/12 | G3NA-800/12 | G3NA-1000/12 | G3NA-1250/12 |

|

Rated Current: |

400A |

630A |

800A |

1000A |

1250A |

| Rated Voltage of Main Circuit (KV) |

12 |

12 |

12 |

12 |

12 |

| Rated Current of Main Circuit (A) |

400 |

630 |

800 |

1000 |

1250 |

| Rated Short-Circuit Breaking Current (KA) |

16 |

16 |

16 |

16 |

16 |

| Rated Short-Circuit Making Current (KA) |

31.5 |

31.5 |

31.5 |

31.5 |

31.5 |

| Rated Peak Withstand Current (KA) |

20 |

20 |

20 |

20 |

20 |

| Mechanical Life (ten thousand times) |

25 |

25 |

25 |

25 |

25 |

| Main Circuit Power Frequency Withstand Voltage (Isolation) (KV) |

42 |

42 |

42 |

42 |

42 |

| Phase-Phase, Phase-Ground Power Frequency Withstand Voltage (KV) |

42 |

42 |

42 |

42 |

42 |

| Lightning Impulse Withstand Voltage (KV) |

75 |

75 |

75 |

75 |

75 |

| Control Circuit Power Frequency Withstand Voltage (KV) |

2.5 |

2.5 |

2.5 |

2.5 |

2.5 |

| Terminal Pressure (N) |

>800 |

>800 |

>800 |

>800 |

>1000 |

| Contact Opening Distance (mm) |

8±1 |

8±1 |

8±1 |

8±1 |

8±1 |

| Overtravel (mm) |

2±0.5 |

2±0.5 |

2±0.5 |

2±0.5 |

2±0.5 |

| Main Circuit Contact Resistance (μΩ) |

≦150 |

≦100 |

≦100 |

≦100 |

≦100 |

| Weight (kg) |

30 |

30 |

35 |

35 |

35 |

The primary difference between permanent magnetic latching type and electrical holding type vacuum contactors lies in the mechanism used for maintaining the contactor in the closed position.

Permanent Magnetic Latching Type Vacuum Contactor:

Operating Mechanism:Utilizes a permanent magnet as the main driving component to keep the contacts closed.

Advantages:Fewer operating elements, simple control, low closing and opening currents, and energy-saving as the control circuit does not require a continuous power supply in the closed or open state.

Application:Suitable for applications where simplicity, reliability, and energy efficiency are important.

Electrical Holding Type Vacuum Contactor:

Operating Mechanism:Relies on an electrical holding coil to maintain the contacts in the closed position.

Advantages:Provides precise control over the contactor's status, and the contacts remain closed as long as the holding coil is energized.

Application:Commonly used in situations where precise control, remote operation, or coordination with other control systems is required.

Need more information?

Contact us to request pricing, availability and customization options.

Compact Medium Voltage Vacuum Contactor EVC4-160A to 630A 12KV

12KV 160A, 250A, 400A, 630A Vacuum Contactor

View More

6.6kV 7.2kV Vacuum Contactor

160A,250A,400A and 630A 6.6/7.2KV single phase casting type vacuum contactors

View More

EVC1-12/160~630-6.3G single pole high altitude 12kv vacuum contactor

630A 12KV. Altitude upto 4000 meters, single phase vacuum contactor.

View More

Single Pole Vacuum Contactor

7.2KV, 12KV, 160A, 250A, 400A and 630A.

View More