Compact medium voltage vacuum contactor

Home Products Vacuum ContactorMedium Voltage Vacuum Contactor (7.2/12kV)Compact medium voltage vacuum contactor

Compact medium voltage vacuum contactor

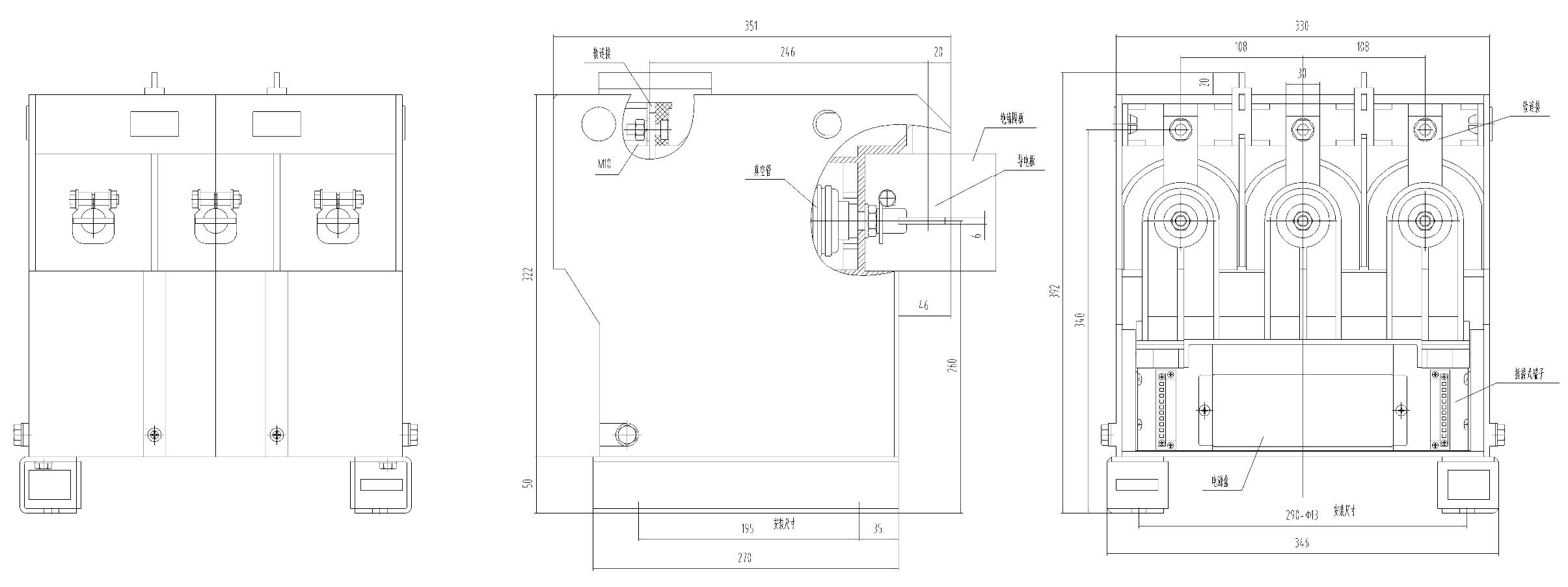

The EVC6-12kV and 7.2KV 400A series AC medium voltage vacuum contactor is a brand-new generation of products developed by our company in response to market demands, capable of fully meeting the latest requirements of the 10kV network. By summarizing years of user experience and combining the latest design concepts of our company, the product is aesthetically pleasing, reliable in performance, easy to use and maintain, and can completely replace imported products. It can be reliably used for switching capacitive loads, such as for making and breaking transformers (AC-6a) and capacitor banks (AC-6b).

| Model | Unit | EVC6-12KV/400A | EVC6-7.2KV/400A |

| Rated Operating Voltage (Ur) | kV | 12 | 7.2 |

| Rated Insulation Level | |||

| 1-min Power Frequency Withstand Voltage (Ud) | kV | 42 | 32 |

| Lightning Impulse Withstand Voltage (Peak) (Up) | kV | 75 | 60 |

| Rated Frequency (fr) | Hz | 50 | 50 |

| Rated Operating Current (Ie) | A | 400 | 400 |

| Rated Single Capacitor Bank Breaking Current (C2) | A | 400 | 400 |

| Rated Back-to-Back Capacitor Bank Breaking Current (C2) | A | — | |

| Short-time Withstand Current | |||

| Rated Short-time Withstand Current (Ik) | A | 6300 | 6300 |

| Rated Peak Withstand Current (Ip) | kA | 16 | 16 |

| Rated Short-circuit Duration (tk) | s | 4 | 4 |

| Rated Operating Frequency | |||

| Electrical Endurance | operations/hour | 600 | 600 |

| Mechanical Endurance | operations/hour | 300 | 300 |

| Rated Load and Overload Characteristics | |||

| 100 Times Closing Operations (Category AC4) | A | 6300 | 6300 |

| 25 Times Opening Operations (Category AC4) | A | 5040 | 5040 |

| Rated Withstand Overload Current for 1s | A | 9450 | 9450 |

| Rated Withstand Overload Current for 30s | A | 3780 | 3780 |

| Main Circuit Contact Resistance | μΩ | <200 | <200 |

| Electrical Endurance | |||

| AC3 | 10*104 times | 25 | 25 |

| AC4 | 10*104 times | 6 | 6 |

Control and Auxiliary Circuits

- Control power supply voltage Us: ac./dc. 110V, 220V, 380V, or customized according to user requirements.

- Control power consumption: Electrical self-holding: starting <2000W, holding <100W. Mechanical self-holding: closing <2000W, opening <1000W.

- Auxiliary contacts: Up to nine sets of normally open and normally closed contact combinations, five sets for mechanical holding.

- Auxiliary contact capacity: AC380V 6A; AC220V 10A.

- Power frequency withstand voltage: 2kV (excluding components).

Operating Characteristics

- Closing and opening time ≤120ms.

- Three-phase synchronism ≤2ms.

- Minimum pick-up voltage ≤85%Us, maximum release voltage = 10%~75%Us.

Main Circuit

- The vacuum switch tube uses products from well-known domestic manufacturers. The technology is mature, quality reliable, and has a good market reputation.

- The main circuit base adopts an integrated molded frame structure, which has good rigidity, minimal deformation, high insulation strength, and good resistance to pollution.

- The 630A current rating uses a double dynamic end connection with end surfaces and conductive clips, resulting in low resistance, low temperature rise, and greater reliability.

- The conductive busbar is aesthetically pleasing, durable, and provides a reliable connection, making it convenient for users.

Electromagnetic System

- Optional permanent magnet mechanism or traditional electromagnetic mechanism.

- Uses a quick-action, high-capacity sealed auxiliary switch, greatly enhancing the reliability of the auxiliary switch and ensuring safe operation.

- The optimized action structure reduces coil start-up power and holding power, resulting in low temperature rise, extended lifespan, and increased reliability.

Operating Structure

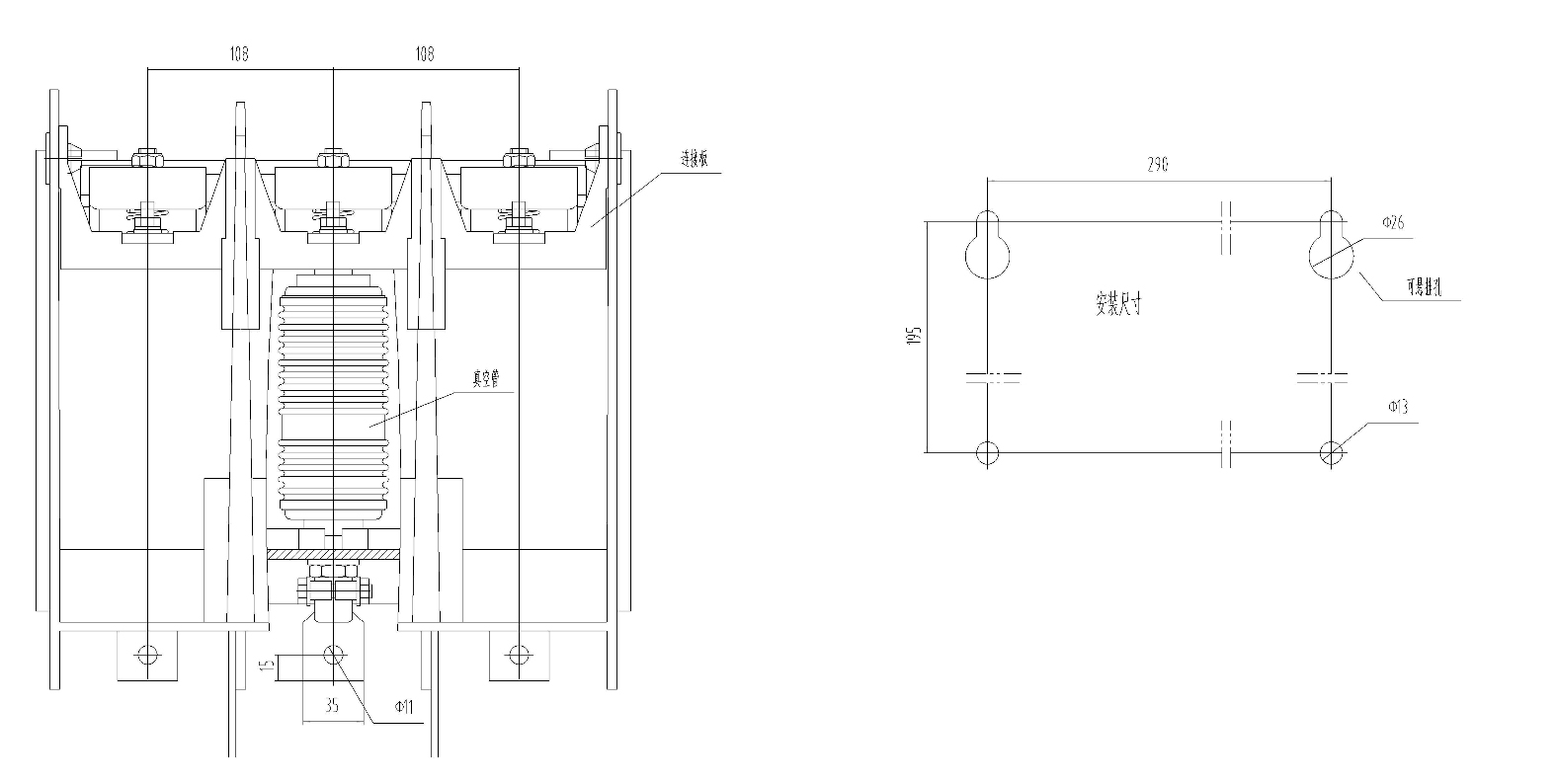

- The main shaft uses self-aligning bearings for flexible support without jamming or axial play, improving operational performance and consistency.

- The moving end uses a secondary guiding mechanism to ensure the axial movement coaxiality of the vacuum tube's moving conductive rod. A reasonable operating mechanism enhances the contactor's performance and reliability. This ensures three-phase synchronism and bounce characteristics superior to similar products.

- Enhanced main contact pressure improves electrical performance and operational characteristics, outperforming similar products.

- The mechanical holding device is integrated, with a reasonable structure for more reliable use.

Ease of Use and Maintenance

- The product body can be installed horizontally or suspended, with mounting holes designed for easy suspension.

- The control circuit connection terminals use universal rail-mounted terminal blocks (plug-in terminal blocks can also be installed according to customer needs), with functional markings to prevent incorrect wiring and facilitate connection. The number of auxiliary contacts can be combined according to user requirements.

Electrical holding

Mechanical holding

- A Terminal block

- CB Power supply box

- K Closing control contactor

- J Closing control relay

- HQ Closing coil

- TQ Opening coil

- SC Closing control switch

- SO Opening control switch

- SA Auxiliary switch

Need more information?

Contact us to request pricing, availability and customization options.

CKG4 12KV Vacuum Contactor

12KV 160A, 250A, 400A and 630A MV vacuum contactor

View More

12KV Latching Hybrid Vacuum Switchgear

12KV, 400A to 1250A, vacuum contactor and vacuum circuit breaker combined vacuum switch

View More

Compact Medium Voltage Vacuum Contactor EVC4-160A to 630A 12KV

12KV 160A, 250A, 400A, 630A Vacuum Contactor

View More

AC high voltage vacuum contactor with fuse composite apparatus

7.2kV and 12kV drawer type removable vacuum contactor, 200A and 315A, fuse limit current protection, breaking capacity up to 40kA.

View More