Bridge Rectifier Modules, Diode Bridge Rectifiers

Robust plastic case with screw terminals, large, isolated base plate, blocking voltage up to 1800V, high surge currents,single phase bridge rectifier & three phase bridge rectifier, easy chassis mounting; widely used for three phase rectifiers for power supplies, input rectifiers for variable frequency drives, rectifiers for DC motor field supplies, battery charger rectifiers.

Differences Between Diode Bridge Modules and Bridge Rectifiers

Both a diode bridge module and a bridge rectifier serve the same fundamental purpose: converting alternating current (AC) to direct current (DC). However, there are some differences in their construction, packaging, and application contexts.

Bridge Rectifier

-

Definition:

- A bridge rectifier is a circuit configuration typically consisting of four diodes arranged in a bridge topology to convert AC to DC.

-

Components:

- It is usually constructed using individual diodes connected in a specific arrangement on a circuit board.

-

Packaging:

- Bridge rectifiers can be found in various packaging forms, including discrete components where each diode is separate, or as integrated units where all four diodes are encapsulated in a single package.

-

Applications:

- Commonly used in power supplies, battery charging circuits, and other applications requiring AC to DC conversion.

Diode Bridge Module

-

Definition:

- A diode bridge module is essentially a bridge rectifier but comes as a pre-assembled, integrated module that includes not just the diodes but also additional components such as heat sinks, protective elements, and sometimes even filtering components.

-

Components:

- It includes the four diodes arranged in a bridge configuration but may also integrate additional features for enhanced performance and protection.

-

Packaging:

- These modules are typically packaged in a more robust and often larger enclosure designed for higher power applications. They might include mounting holes for easy installation and may come with improved thermal management solutions.

-

Applications:

- Used in industrial applications, motor drives, high-power power supplies, and other scenarios where higher current and voltage ratings are required. They are designed for more demanding environments where reliability and durability are critical.

Key Difference

-

Construction:

- Bridge Rectifier: Often constructed using discrete diodes or as a single integrated package.

- Diode Bridge Module: A more comprehensive unit that may include additional components and features beyond just the diodes.

-

Packaging:

- Bridge Rectifier: Can be found in small, compact packages suitable for lower power applications.

- Diode Bridge Module: Typically larger, more robust, and designed for higher power applications with better thermal management.

-

Applications:

- Bridge Rectifier: Suitable for general-purpose AC to DC conversion in various electronic devices.

- Diode Bridge Module: Suitable for industrial and high-power applications where enhanced durability and performance are needed.

-

Ease of Use:

- Bridge Rectifier: May require additional components like heat sinks or protective elements depending on the application.

- Diode Bridge Module: Often comes as a ready-to-use unit with integrated features that simplify installation and improve reliability.

In summary, while both serve the same basic function of converting AC to DC, diode bridge modules are designed for more demanding applications with higher power requirements and often come with additional features that enhance their performance and reliability.

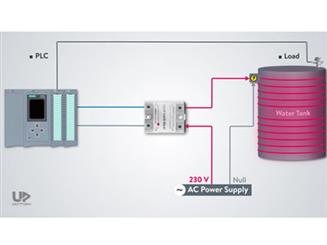

How solid state relays work? Testing SSR with multimeter and wiring.

How solid state relays work? Hoto to Test a solid state relay with multimeter? How to connect a SSR relay from PLC to heater? You will get an answer.

Read More

What is the main difference between 8/20μs and 10/350μs in SPD?

8/20μs: Suitable for protection against fast-rising and short-duration surges, such as lightning strikes and rapid switching events.10/350μs: Suitable for protection against slower-rising and longer-duration surges, often associated with power distribution network switching operations and industrial electrical systems.

Read More

Advantages of Low Voltage Drop DC Solid-State Relays - Heatsink is not required

Low voltage drop DC solid-state relays offer significant advantages in terms of efficiency, low heat generation, and high reliability, making them particularly suitable for applications requiring high efficiency and low energy consumption.

Read More

Solid State Relay: A Comparison of PLC Interface and Panel Mount

Differences Between PLC Interface and Panel Mount Solid State Relays

Read More