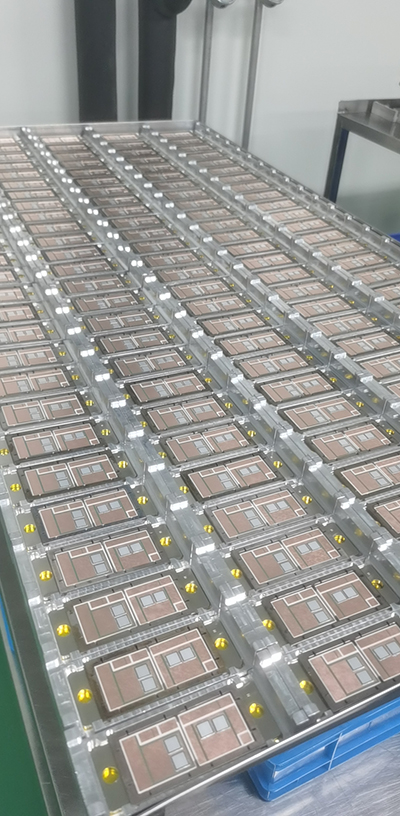

Sintering process in the chip of solid-state relays is of significant importance.

The use of sintering process in the chip of solid-state relays is of significant importance, primarily for the following reasons:

Product Quality and Reliability

The sintering process ensures high-quality and reliable chips. Through high-temperature sintering, the internal materials of the chip fuse effectively, forming a robust structure. This enhances the relay's resistance to vibration and impact, thereby improving stability and lifespan.

Electrical Performance

The sintering process contributes to consistent electrical performance within the chip. By controlling temperature and time during sintering, electronic components inside the chip can be evenly distributed, reducing variations in parameters such as resistance and capacitance. This improves the electrical performance of the relay, ensuring it operates reliably under various conditions.

Thermal Performance

Solid-state relays may generate heat during operation, and the sintering process helps enhance the chip's heat dissipation capabilities. This is crucial for the stability and reliability of the relay, especially during high-load and high-frequency operations.

Environmental Protection and Energy Efficiency

Sintering processes typically involve environmentally friendly, low-pollution techniques at high temperatures. Compared to some traditional manufacturing processes, sintering has a lower environmental impact. Additionally, improving the chip's electrical and thermal performance can reduce energy consumption, contributing to energy efficiency.

Therefore, choosing solid-state relays with chips manufactured using the sintering process ensures high-quality, reliability, and environmental suitability, making them well-suited for various industrial applications.

Advanced Low-Power Short-Range Millimeter-Wave Radar Module: Features and Applications

Low Power Short Range Millimeter-Wave Radar Module, the Preferred Choice for Smart Security and Smart Door Lock.

Read More

Difference Between Stud-Type and Capsule-Type Phase-Controlled Thyristors (PCT)

Capsule-type is better suited for higher power and more demanding heat dissipation requirements, while Stud-type is more appropriate for medium power applications with simpler installation needs.

Read More

Guide to Heatsink Calculation and Selection

A heatsink is a device used for heat dissipation, commonly found in electronic devices to help dissipate heat and prevent overheating.

Read MoreAdvantages of Low Voltage Drop DC Solid-State Relays

Low voltage drop DC solid-state relays offer significant advantages in terms of efficiency, low heat generation, and high reliability, making them particularly suitable for applications requiring high efficiency and low energy consumption.

Read More