You are here: Home > Products > DC SSR Relay

|

Model |

GZ10S / GZ10SL |

||

|

Input |

Control Voltage |

12~15VDC; 18~36VDC |

|

|

Control Current |

≤80 mA |

||

|

Start Current |

≥ 60 mA |

||

|

Turn off Voltage |

12~15VDC≤10VDC; 18~36VDC≤12VDC |

||

|

Output |

Switching On/off time |

≤ 0.35 mS |

|

|

Max. Voltage |

60V, 100V, 200V, 600V, 1200V |

||

|

Max. Current |

30~400A |

||

|

On state voltage drop |

60V≤0.5V, 100V≤0.8V, 200V≤1.5V, 600V≤4.2V, 1200V≤5.0V |

||

|

Off state voltage |

60V, 100V, 200V, 600V, 1200V |

||

|

Protection |

Blank - without protection, L - with over-current and short-circuit protection, @ 50% of rating current. |

||

|

Performance Parameters |

Isolation Voltage |

≥ 2000 V |

|

|

Insulation Voltage |

≥ 2500 V |

||

|

Temperature Range |

-30 ~ 75 ℃ |

||

|

Power frequency |

10-1000 HZ |

||

|

Heatsink |

Install a heat sink with a fan |

||

|

Load tips |

For resistive loads, use 2-3 times the rated value. For inductive loads, use 3-4 times the rated value. |

||

|

Dimensions |

95×39×40mm or 120×52×32mm |

||

|

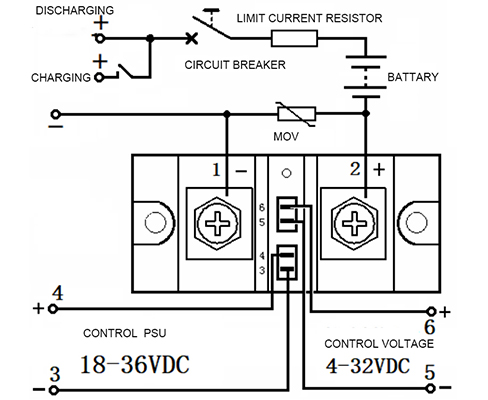

Model |

GZ10CS / GZ10CSL |

||

|

Input |

Control power supply |

12~15VDC/2W; 18~36VDC/2W |

|

| Control Voltage | 4-32VDC | ||

|

Control Current |

8-20 mA |

||

|

|

|||

|

Turn off Voltage |

12~15VDC≤10VDC; 18~36VDC≤12VDC |

||

|

Output |

Switching On/off time |

≤ 0.15 mS |

|

|

Max. Voltage |

60V, 100V, 200V, 600V, 1200V |

||

|

Max. Current |

30~200A |

||

|

On state voltage drop |

60V≤0.5V, 100V≤0.8V, 200V≤1.5V, 600V≤4.2V, 1200V≤5.0V |

||

|

Off state voltage |

60V, 100V, 200V, 600V, 1200V |

||

|

Protection |

Blank - without protection, L - with over-current and short-circuit protection, @ 50% of rating current. |

||

|

Performance Parameters |

Isolation Voltage |

≥ 2000 V |

|

|

Insulation Voltage |

≥ 2500 V |

||

|

Temperature Range |

-30 ~ 75 ℃ |

||

|

Power frequency |

10-1000 HZ |

||

|

Heatsink |

Install a heat sink with a fan |

||

|

Load tips |

For resistive loads, use 2-3 times the rated value. For inductive loads, use 3-4 times the rated value. |

||

|

Dimensions |

95×39×40mm or 120×52×32mm |

||

We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies.