Gas-Filled Relays vs. Vacuum Relays: A Comparison and Application in High Voltage Switching Technology

Gas-filled relays and vacuum relays are both electrical devices used for high voltage switching, but they have some differences in structure and application.

Gas-filled relays are filled with gas, usually an inert gas such as nitrogen or sulfur hexafluoride (SF6), which helps extinguish the arc when switching high voltages. Gas-filled relays can handle very high voltages and currents and are commonly used in power transmission and distribution systems.

Vacuum relays operate within a vacuum chamber. The vacuum environment prevents arc formation, allowing them to handle high voltages more efficiently and reduce contact wear. This also enables the relay to switch faster than those in the air. Vacuum relays are durable, compact, and operate quietly, making them ideal for applications requiring rapid switching and control of high voltage circuits, such as RF transmission and power distribution systems.

Both provide reliable solutions for high voltage applications, but vacuum relays are particularly suited for situations requiring fast switching due to their quick response and low wear characteristics.

How to choose a suitable Solid State Relays

Single phase or three phase, nominal voltage and current, potential surge or inrush current, AC or DC load, control signal, zero crossing type or random control ssr etc.

Read More

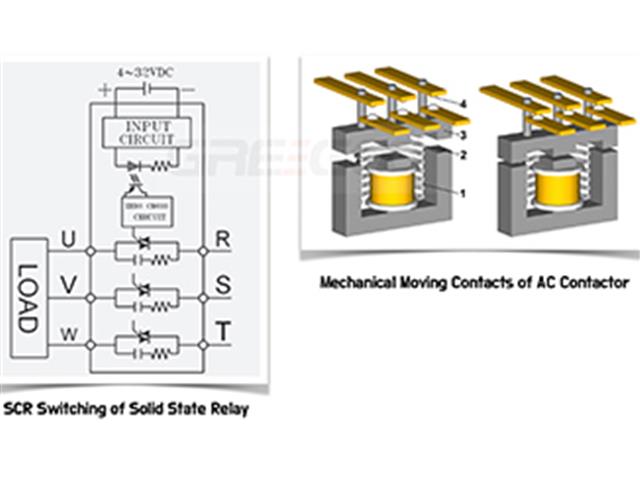

Comparison of Solid State Relays and AC Contactors in Terms of Instantaneous Current Withstand Capability

Therefore, in applications that require handling high instantaneous currents, AC contactors are usually more suitable than solid state relays.

Read More

Vacuum Contactor vs. AC Contactor, What is the Differences?

Vacuum contactors provide superior durability and low maintenance for high-voltage systems, while AC contactors are cost-effective and versatile for lower-voltage needs.

Read More

Transform Your Smart Security and Doorbell Solutions with Our Advanced Millimeter-Wave Radar Module

We are excited to introduce our latest innovation in smart technology – the Low Power Short Range Millimeter-Wave Radar Module, designed to revolutionize your smart security and doorbell solutions.

Read More